Gating ratio and its functions. 23 Determinedecide on total.

Gating System For Casting Excellent Animation Youtube

DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and design of gating system.

. Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the. A key element in producing quality castings is the proper design and sizing of the gating and riser systems. The objective of project is to design and simulate gating and risering system components by using simulation technology to get defect free casting.

Feeding and Gating System Design and Simulation of Flange Roller of Hydrators for Yield Melioration PDChauhan1 Mohit Anuvadiya2Vivek Chauhan3 1Assistant Professor 2 3BE. The gating system refers to channels through which the metal flows from the ladle to the mold cavity. Casting simulation does not provide the initial riser design for a casting.

Properly made gating system and riser confirmed the uniform and finished filling of clean molten metal. There should not be any discontinuity or solid inclusions. Metallurgical engineering and materials science afs method afs cmi publishes a handbook entitled basic principles of gating and risering a model of a casting only with no risers gating or chills.

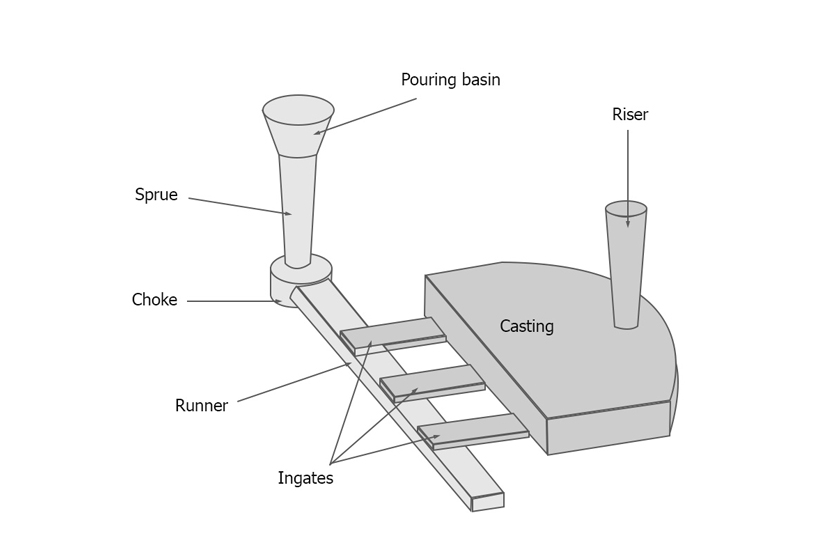

Risers have been designed and placed such that the whole casting is free from shrinkage. The gating system is composed of Pouring basin Sprue Runner Gates Risers Pouring basin-. To be able to obtain a sound casting the gating and riser design plays a pivotal role in the sand casting process.

Students Production Engineering Department BVM. On the success of gatingriser system design which is currently conducted mainly relying on the technicians experience. It may experience different defects such as crack porosity hot tear etc.

GATING SYSTEM PPT 1. The velocity and temperature determine the solidification of molten metal in casting. ELEMENTS OF GATING SYSTEM 1Pouring basin 4.

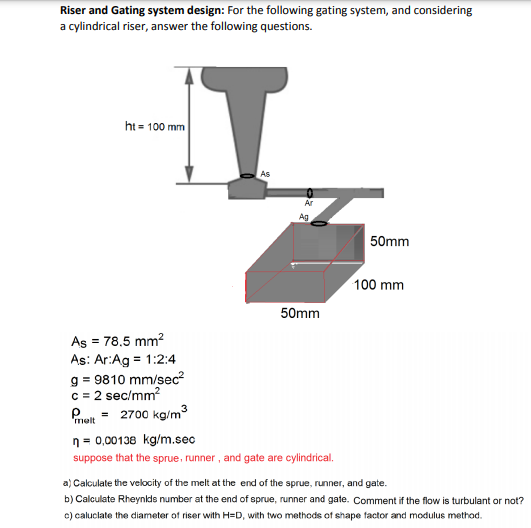

Riser and Gating Design GATING SYSTEM- The term gating system refers to all passageways through which the molten metal passes to enter the mould cavity. Emphasis will be placed on hands-on activities animations and simulations to enhance understanding of the filling and solidification processes in a foundry. Gating and risering system design revised in 2000 department of 2 25.

CONCEPT OF GATING AND RISERING DEFINTION TYPES OF GATES GATING DESIGN GATING RATIO RISERING TYPES FUNCTIONS 3. The present rules can be used to develop the first trial riser design. Because of poor design of gating and risering system.

The gating system of sand casting is designed to direct the liquid to the mould cavity metal for filling. An introduction to fluid flow and solidification will serve to guide participants through key design concepts of the various functional elements of good gating and riser design. Definition and functions of the riser.

The main objective of a gating system is to lead clean molten. Software can be used in place of actual casting trials to detect feeding and risering problems in a steel casting the present rules still serve several important purposes. Gating and riser system are designed with the help of mathematical formulae.

The objective of the project is to optimize gating and. Runner 2Down sprue 5. The objective of the research presented in this thesis is to optimize gatingriser systems based on CAD and simulation technology with the goal of improving casting quality such as reducing incomplete filling area decreasing large porosity and increasing yield.

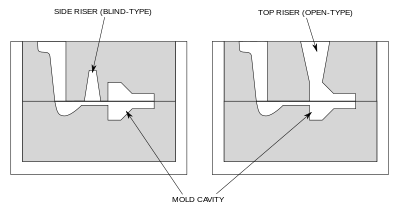

Design of the riser - its shape. Casting is suitable economical manufacturing process for various components. The riser system is direct to counterbalance shrinkage cause by.

Types of risers and their application. Components of the gating System and its functions. Casting simulation utilizes finite element procedures depending upon the complexity of the problem.

Contents Introduction Elements of Gating System Functions of gating system Defects occurring due to improper design of gating system Types of Gates Pouring Time Gating Ratio Guidelines for Designing Gating System Review of papers Conclusion. Gating Riser Design SUBSCRIBE NOW Modules Basics of Fluid Dynamics for Metalcasting Gating Systems This module examines the basics of fluid dynamics for metalcasting gating systems and defines fluid flow in gating systems. Seminar on Gating System JAGANNATH MTechCIM MSRIT 1MS16MCM08 2.

Detailed examples are also given to explain the implementation of these rules and procedures. Design and Analysis of Gating and Risering System for Casting of Ball Valves. We can call a gating system a basic design.

Chapter 4 Gating System Risering fOne of the key elements to make a metal casting of high quality is the design of a good gating system. The gating system helps in controlling turbulence and the rate of molten metal to be poured. Designing a gating system in a purely scientific way demands through knowledge in the thermal and fluid dynamics field.

Different types of gates. On the other hand the paper presents a useful summery of a list of the most important references related to the design of Gating and Risering systems in sand casting. It reviews in a simplified and comprehensive way the most important practical and scientific rules and procedures related to Gating and Risering systems design.

Risers are used to compensate for liquid shrinkage and solidification shrinkage11 1No shrinkage defects. Bad design of the gating and feeding system can result in defects in the castings. A good gating system will helps in directional solidification in casting.

One of the main variables that should be considered when designing a gating system is the flow of molten metal while filling the mould. This paper is a review paper. GATING Gating are flow passages to run and fill molten metal in mould cavity.

So the study helps to create an optimum design of gating system for a windmill hub. Gatingriser system design is critical to improving casting quality. Gating Risering System Gating system is to lead clean molten metal poured from ladle to the casting cavity with less turbulence.

Design of the gating system. Module 5 - Principles of Gating and Risering Purpose of the gating system. Though we have a number of scientific approaches to the design of the gating and risering most foundries still prefer to have the traditional way of designing gating feeding systems by trials and experimentations.

This module also defines the laws of fluid dynamics and the effects of momentum and turbulence on gating systems. Its essential to build a smooth and proper filling of the mould cavity of the casting. It provides a large range of the complete behavior of the casting during solidification.

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

How To Design Gating System Correctly R Metalfoundry

Riser And Gating Design Engineers Knowledge

Gating System In Mold Mechtech Guru

Elements Of A Gating System Rao 2001 Download Scientific Diagram

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Solved Riser And Gating System Design For The Following Chegg Com

0 comments

Post a Comment