LD 5 Other options available by additional machining Holes diameter 15 mm. LD 2 Lower side.

This process is repeated layer-by-layer using a map from a digital design file.

. Manufacturers use many sheet. This is due to the similarities in the molding process. Get a Quote Today.

Ad Leader in Powder Metal Parts Manufacture. ROBUST TOOLING Ratio between depth and diameter in blind holes. For another reference guide molders may turn to Metal Injection Moulding reprinted by the European Powder Metallurgy Assn.

1 Powder supply is raised placing feedstock material in front of recoater 2 Recoater moves across the powder bed distributing a layer of powder on the build platform 3 A laser locally. With 175 pages of user-friendly information and over 75 photos and illustrations the PM Design Manual is now more important than ever before. High strength corrosion resistance and durability properties that are characteristic of each base metal.

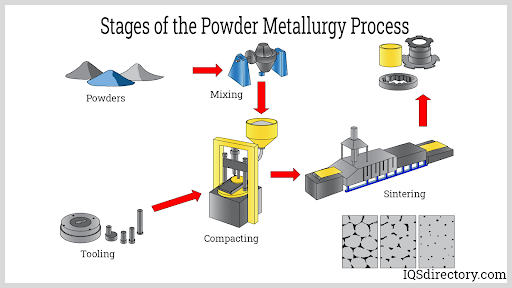

Ad The characteristics of excellent fluidity high apparent density low hollow powder ratio. Powder metallurgy is a metal-forming process performed by heating compacted metal powders to just below their melting points. This guide is based on Powder Injection Molding.

The third edition of this. Deposits a bonding agent onto a thin layer of powdered particles either metal sand ceramics or composites. Ratio is about 60 vol.

The technology encompasses multiple processes including. World leading metal additive manufacturing solution supplierProvide High Quality product. Small powder sizes typically 25 um can be used in MIM smaller than the powder used in traditional powder metallurgy.

Fortunately the MIM process provides a level of. The small size leads to a relatively high amount. Get a Quote Today.

Depending on the metal powder aluminum is light tungsten is heavy a steel or stainless steel mixture constitutes. Metal Injection Molding Design Guide MIM design is similar to plastic molding design. Important design advantages of porous PM parts include.

Ad Leader in Powder Metal Parts Manufacture. Sheet metal fabrication is a product manufacturing process that involves turning thin flat pieces of metal into pre-programmed structures. Powder requiring then about 40 vol.

Powder Metallurgy Design Tips Atlas Pressed Metals

Powder Metallurgy Design Tips Atlas Pressed Metals

Designing For Powder Metallurgy

Design Guidelines For Powder Metal Processing Youtube

Pdf Design For Powder Metallurgy Pm Process Hidayah Hidzir Academia Edu

Powder Metallurgy What Is It Processes Parts Metals Used

Powder Metallurgy Design Manual Standard Pdf Standard Pdf Site

Metal Injection Molding Design Guide From Advanced Powder Products Inc

0 comments

Post a Comment